医药行业的数字技术PLM产品研发生命周期管理系统,PLM为什么适用医药行业

医药行业的数字技术PLM系统,PLM为什么适用医药行业?数字化转型网有关于医药行业的数字化转型资料及数字化转型案例。

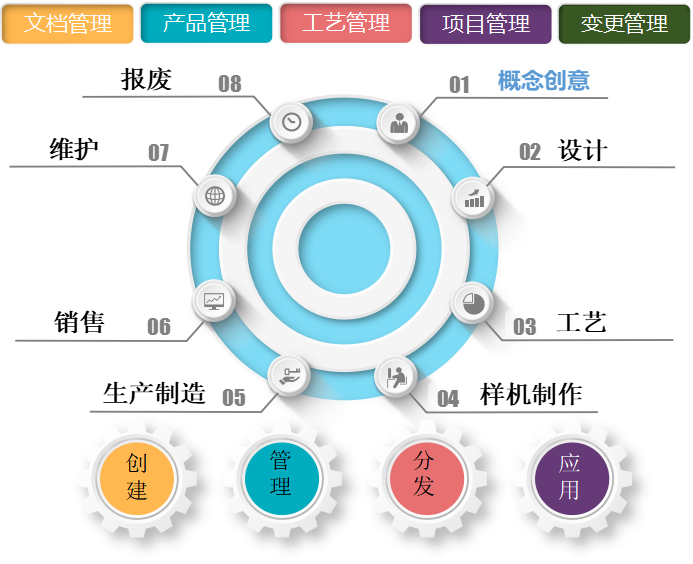

依据IPD管理理念,对标 “医药行业” 研发管理模式,建立PLM系统研发项目管理平台,使医药企业实现从“项目启动、项目规划、项目执行、项目监控、项目收尾”的完整生命周期管控。PLM系统使医药企业实现业务环节的数据打通,PLM系统使医药企业共享完整的研发信息,PLM系统使医药企业提升各阶段/环节的研发任务效率。

PLM系统帮助医药企业提升具体包括:

1、PLM系统使医药企业标准化:为了提升研发业务的标准化与规范化管理,PLM系统建立对标管理模式,PLM系统以标准驱动研发业务的开展,PLM系统降低人为因素对业务的干扰,同时不断优化与积累医药项目中的经验,通过对标准的积累,包括进度组织标准、流程标准、交付成果标准,最终实现项目的过程与标准的无缝对接与融合。

2PLM系统使医药企业协作效率提高:为了缩短研发项目的时间,PLM系统建立PMO与PI二级的任务管控模式,在系统可自动化的按研发的业务过程,对资源分发与其相关的任务内容,并关联其任务开展所需要的所有要素(如:流程、交付成果、注意风险等),减少PMO与PI在项目中的协调与管理成本,加速研发项目的开展的效率。

3、PLM系统使医药企业减少过程风险:为了避免研发过程中产生的风险事项,PLM系统建立问题与风险监督体系,通过PLM系统医药企业可监控计划与执行偏差、项目的风险识别与整改,动态化预警出现的问题和风险,提升医药企业项目的风险控制能力。

4、PLM系统使医药企业降低人力资源成本:为了降低研发过程中的人力资源成本,PLM建立人才的大数据库,并联动医药企业项目的品类管线与重要等级维度,使医药企业做到项人匹配,同时为了激励医药企业人员的积极性,建立量化的绩效分配模式,以医药企业内部人员参与里程碑完成的质量与周期作为评定标准,量化考核人员的研发产出,便于领导对优秀人才的选拔与激励。

根据数字化转型网(搜索栏输入:中国数字化转型网,即可了解详情)的资料,PLM是企业数字化转型非常重要的一环。根据数字化转型网的PLM研究报告,PLM是医药、化工行业、服装行业、机械装备制造业行业、电子机电行业、汽车、汽车零部件行业、家具家电、消费品等行业企业必须具备的管理系统软件,在行业数字化转型中起到非常重要的作用。

数字化转型网也提供大量的关于PLM报告、数字化转型资料报告,如果您想了解更多关于数字化转型的知识、方案、报告、资料,建议一定要去看看哦。

翻译

The digital technology PLM system of medicine industry, why PLM is suitable for medicine industry? Digital transformation network has digital transformation information and digital transformation cases about the pharmaceutical industry.

According to the IPD management concept, the research and development management mode of "pharmaceutical industry" is standardized, and the PLM system research and development project management platform is established, so that pharmaceutical enterprises can realize the complete life cycle control from "project start, project planning, project execution, project monitoring and project closure". PLM system enables pharmaceutical enterprises to achieve business link data access, PLM system enables pharmaceutical enterprises to share complete research and development information, PLM system enables pharmaceutical enterprises to improve the efficiency of research and development task at each stage/link.

PLM system helps pharmaceutical enterprises improve, including:

1. PLM system standardizes pharmaceutical enterprises: In order to improve the standardization and standardized management of R&D business, PLM system establishes a benchmarking management mode. PLM system drives the development of R&D business by standards, reduces the interference of human factors on business, and continuously optimizes and accumulates experience in pharmaceutical projects. Through the accumulation of standards, including schedule organization standards, process standards, and deliverable standards, The final realization of the project process and standard seamless docking and integration.

2. PLM system improves the collaboration efficiency of pharmaceutical enterprises: In order to shorten the time of R&D projects, PLM system establishes the PMO and PI level task management and control mode, in which the system can automatically distribute its related tasks according to the business process of R&D, and associate all the elements required for its task development (such as: Process, deliverables, attention to risks, etc.), reduce the coordination and management costs of PMO and PI in the project, and accelerate the efficiency of R&D projects.

3. PLM system enables pharmaceutical enterprises to reduce process risks: In order to avoid risks arising in the process of research and development, PLM system establishes a problem and risk supervision system. Through PLM system, pharmaceutical enterprises can monitor deviations from plan and execution, identify and rectify project risks, dynamically warn problems and risks, and improve the risk control ability of pharmaceutical enterprises.

4. PLM system enables pharmaceutical enterprises to reduce human resource costs: In order to reduce the cost of human resources in the process of research and development, PLM establishes a large database of talents, and links the category pipeline and important level dimension of the pharmaceutical enterprise project, so that the pharmaceutical enterprise can match the project personnel. At the same time, in order to stimulate the enthusiasm of the pharmaceutical enterprise personnel, it establishes a quantitative performance distribution model. With the quality and cycle of the pharmaceutical enterprise's internal personnel participating in the completion of milestones as the evaluation criteria, the quantitative assessment of personnel's R & D output is convenient for leaders to select and motivate outstanding talents.